Lubrication is vital for multiple parts of the compression process. Therefore, it's important to know which oil is best for your air compressor and why you should use it.

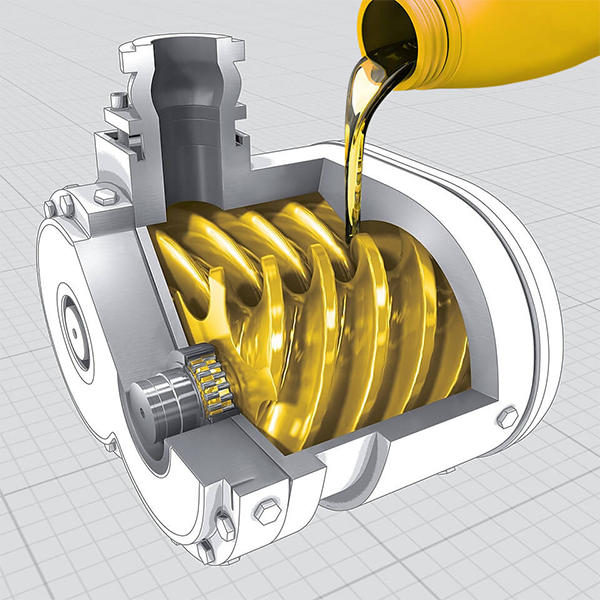

Screw compressor oil is essential for compressor operation.Screw compressors require oil to provide a number of essential functions:

Cooling and heat dissipation

When compressing gas, a lot of heat is generated. Lubricating oil can absorb the friction heat of the rotor and the heat of gas compression, and dissipate the heat generated during the compression process through the oil circuit circulation to prevent overheating.

Without lubrication, the compressor temperature is too high, and the components or all rotating parts will be subjected to stress, which will cause material deformation, seal failure, and shorten its service life.

Lubrication and wear reduction

Lubricating oil can cover moving parts such as bearings and shaft seals to prevent friction and wear of moving parts (especially rotors).

When the rotor of the screw compressor rotates at high speed, there is a small gap between the tooth surfaces, but the contact between metals can cause operating problems and premature failure.

Noise reduction and vibration reduction

Lubricating oil forms a buffer layer between the rotors, which can act as a sound barrier and reduce compressor noise.

Especially for oil-free screw compressors (sealed by other means), although the gas is not directly lubricated, bearings and other components still need lubricating oil to reduce vibration and noise.

Leakage prevention

After the lubricating oil fills the gap, it can form a seal, reduce gas backflow, and effectively prevent leakage between the rotor and the housing, thereby achieving efficient compression.

The gap between the rotor teeth can cause compressed gas to leak, affecting the compression efficiency.

Cleaning and corrosion prevention

The flow of lubricating oil can capture pollutants and impurities entering the air and protect internal components.

Lubricating oil additives can form a protective layer on the metal surface to prevent moisture or acidic substances from corroding the rotor or body.

When should the screw compressor oil be changed?

There are several factors to consider when determining the appropriate replacement time for screw compressor lubricants:

Operating hours: The number of operating hours of the compressor

Lubricant type: The service life of the lubricant depends on the type of lubricant.

Compressor load: The higher the load, the more frequent the lubricant may need to be replaced.

Lubricant filtration: Is the lubricant filtration system operating effectively to maintain the quality of the lubricant?

Environmental conditions: Harsh operating environments such as high temperature, dust, and humidity may require more frequent lubricant changes.

Hope the above content is helpful to you. Qingdao Futai is your one-stop supplier of all air compressor parts to keep your air compressor at its best performance. If you are interested in our products and want to know more, please click the message icon in the lower right corner and select the contact information you want to use to contact us.