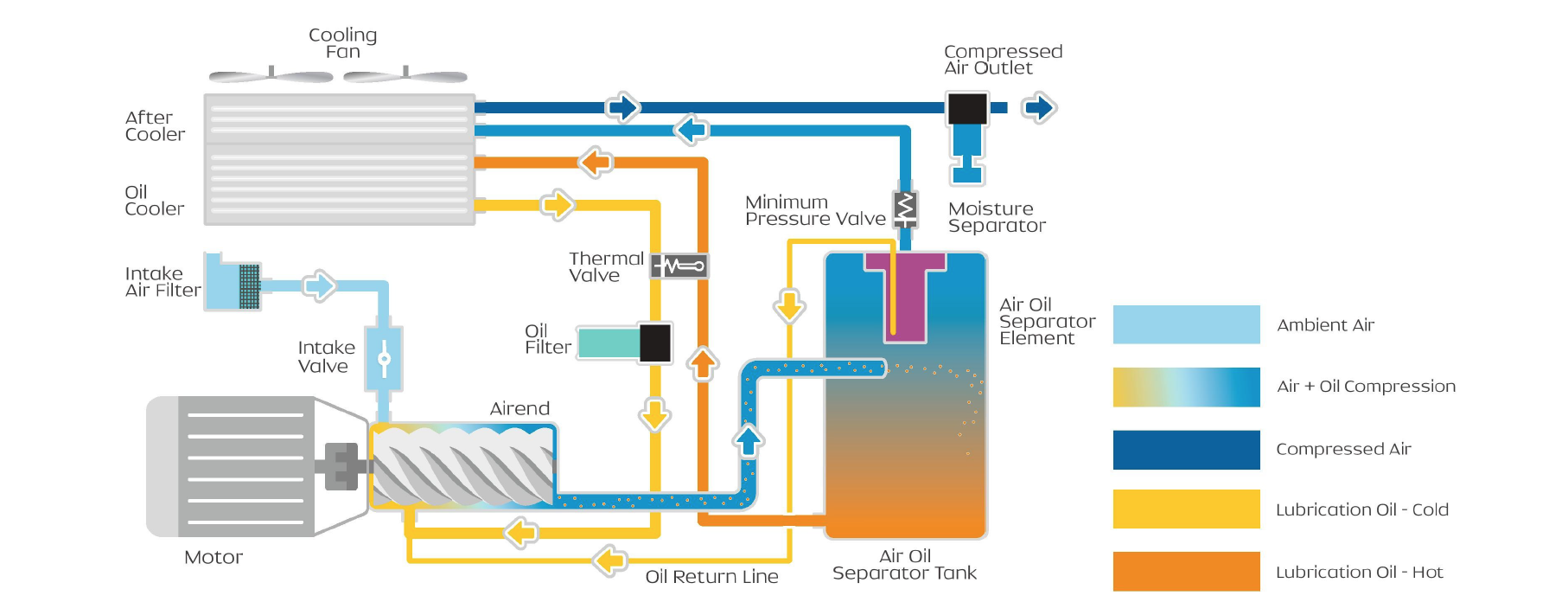

The oil separator in the screw air compressor is one of the core components. Its function is to separate the mixture of compressed air and lubricating oil to ensure the output air is clean and reduce lubricating oil consumption.

Under normal operation, the service life of the oil separator is about 3000 hours, but the quality of the lubricating oil and the filtration accuracy of the air have a huge impact on its life. Long-term use of the filter element will be clogged by oil and impurities, resulting in reduced filtration efficiency, increased oil content in the compressed air, and affected gas quality.

With the accumulation of impurities, the pressure difference before and after the oil separator increases, increasing the operating load of the air compressor, increasing energy consumption, and even triggering a high temperature alarm. The oil separator must be replaced when it expires or the pressure difference before and after exceeds 0.12Mpa.

If the oil separator is severely clogged, it may cause abnormal exhaust pressure of the air compressor, damage to the oil separator core or tripping of the safety valve, causing oil leakage or equipment failure, affecting the normal operation of the equipment.

Replacement method: Shut down and cut off the power supply to ensure that the air compressor is in a completely depressurized state. Remove the control pipe joint installed on the oil and gas barrel cover. Take out the return oil pipe on the oil and gas barrel cover that extends into the oil and gas barrel, and remove the fastening bolts of the oil and gas barrel cover. Remove the oil and gas barrel cover and drain the oil. Remove the asbestos pads and dirt stuck on the upper cover. Install a new oil separator, and note that the upper and lower asbestos pads must be fixed with staples. When pressing down, the asbestos pads must be placed neatly, otherwise it will cause punching of the gasket. Reinstall the upper cover, return oil pipe and control pipe as they were, and check for leaks.

Be sure to use original or equivalent oil separator. Poor quality oil separator may lead to insufficient separation efficiency or explosion risk. When replacing oil separator, it is recommended to check the status of air filter, oil filter and lubricating oil simultaneously to avoid secondary damage of pollutants to the new oil separator. In high temperature environment, wait for the equipment to cool down before operating to prevent burns or oil and gas explosion.

Qingdao Futai is your one-stop supplier of all air compressor parts to keep your air compressor at its best performance. If you are interested in our products and want to know more, please click the message icon in the lower right corner and select the contact information you want to use to contact us.