Why do you need dry compressed air?

The compressed air output by the screw air compressor usually contains moisture (humid air from the atmosphere). The moisture exists in gaseous state under high temperature and high pressure, but condenses into liquid water after cooling, causing: corrosion of pipelines and equipment; affecting the operation of pneumatic tools and instruments; contaminating products (such as spraying and food industries), etc.

Refrigerated dryers, based on efficient, simple technology, are the preferred solution for most applications.

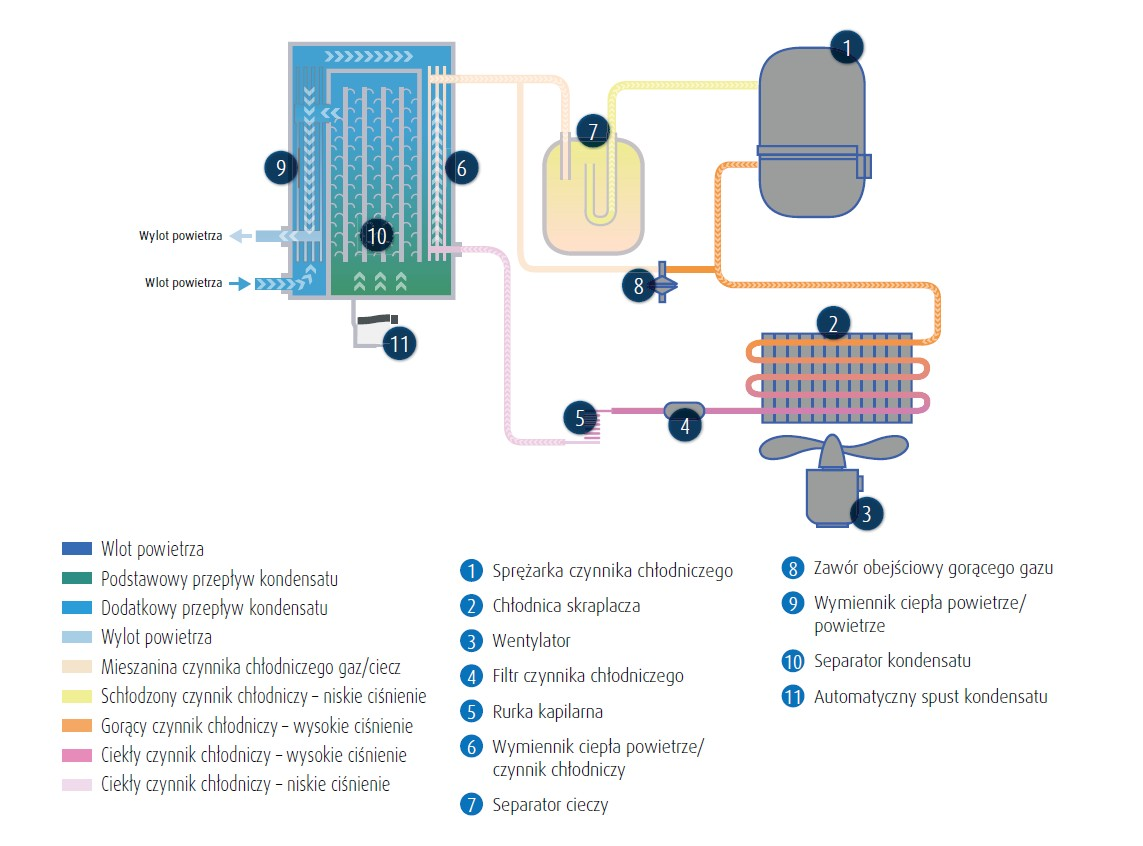

The compressed air discharged from the screw air compressor first enters the heat exchanger to exchange heat with the cooled and dried air to initially reduce the temperature. Then it enters the evaporator of the refrigeration system, where the compressed air is cooled to below the dew point temperature, causing the water vapor in it to condense into liquid water. This liquid water is discharged through the drainage device, thereby reducing the moisture content in the compressed air. Finally, the cooled and dried air is heated up by the heat exchanger to avoid condensation due to low temperature during transportation.

Through the above method, the compressed air output by the screw air compressor can reach the required dryness, ensuring system stability and gas quality.

Hope the above content is helpful to you. Qingdao Futai is your one-stop supplier of all air compressor parts to keep your air compressor at its best performance. If you are interested in our products and want to know more, please click the message icon in the lower right corner and select the contact information you want to use to contact us.